From a Simple Bean to Millions of Bottles of Wonderful Flavors

Before I dove into the culinary world professionally head-first, soy sauce was just a background item in my kitchen. It was always there but I never really cared to learn about it in depth. Born and raised in China, soy sauce is an essential cooking sauce for Chinese food. Almost every dish we cook requires soy sauce. It is salty, savory, and gives food color.

When I was a kid, soy sauce seemed to be only one variety, there was no light or dark, it was a simple sauce that both added flavor and color. It wasn't until the past two decades that new varieties of soy sauce came into our lives.

The Epiphany

With fermentation being a project of my own, many ordinary ingredients and condiments have been re-evaluated through a new lens. Soy sauce is one of them. From the raw ingredient to the fermentation process, to its variety of applications in our modern life, I am in awe of how we can utilize such a simple ingredient to yield so many different and meaningful results. This newfound perception is thanks to a journey to Luzhou by the Yangtze River. Through the hospitality of a soy sauce factory, we learned the whole process of making soy sauce.

Our Journey Begins

We arrived at the picturesque Chishui River where the soy sauce factory is located. As soon as we entered it felt like we walked into an ancient traditional Chinese house. Old architecture, intricately carved wooden window frames and detailing, old tyle rooftops, it was something out of a history book. With a long history of making soy sauce in Luzhou, they certainly held tightly to their traditions in all aspects for the past 130 years.

We were guided through the old halls out behind the buildings to a grand open space filled with the urns of fermenting soy beans. The long arduous process of drawing out the rich, nearly black liquid we call soy sauce.

Pictures don't do it justice. The smell coming from the urns is intoxicating. The rich smell of pure soy sauce fills the air. The nearby river down the hillside adds a layer of natural beauty to the atmosphere and everything feels serene.

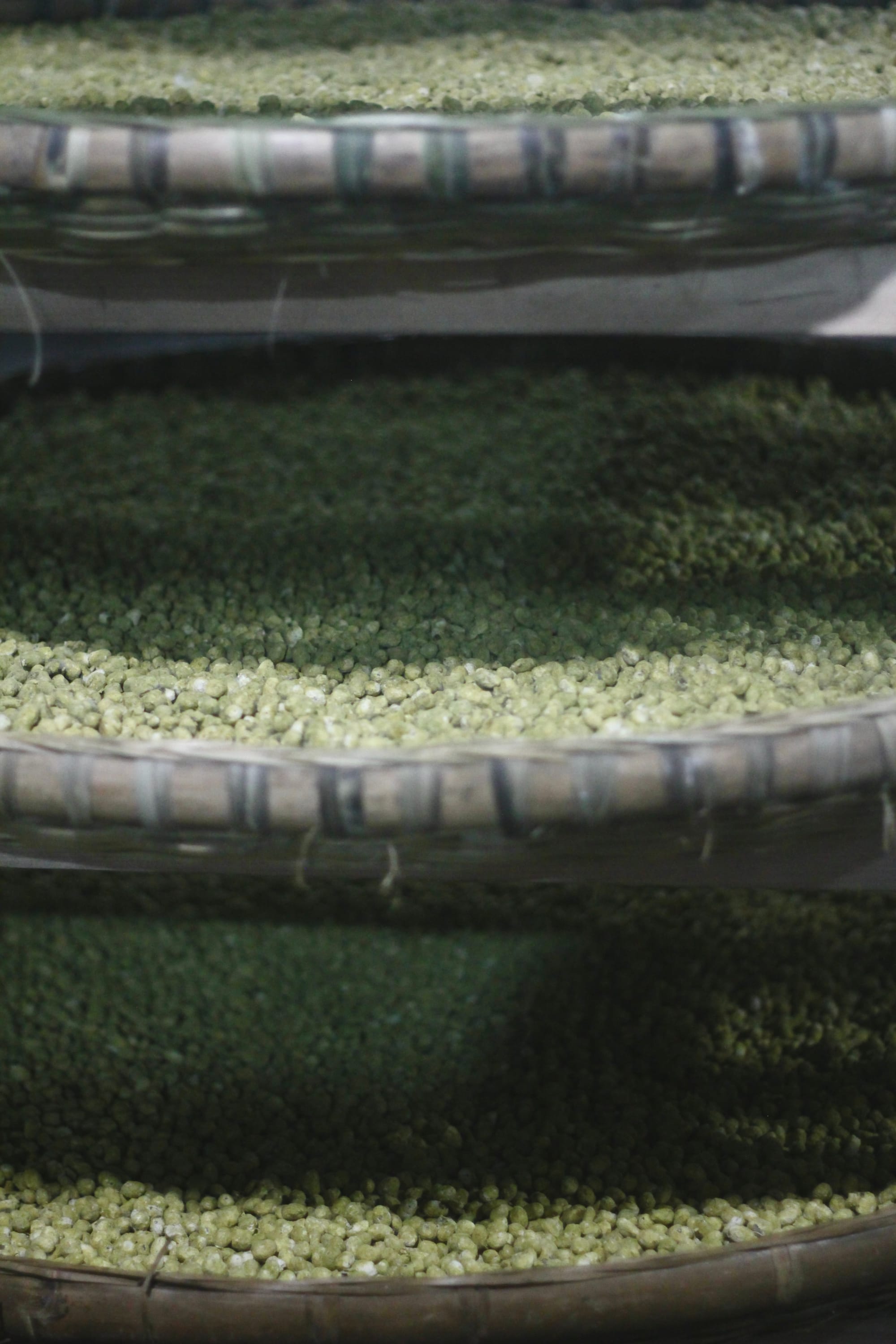

The giant steaming basket they use in the soy sauce factory to cook the soy beans, it takes 2 professional workers to lift it and spread the soy beans. / The shifu (master of one profession) is spreading the steamy soy beans with a wooden spatula on a flat tray before they coat them with flour.

We are then led into the building where they prepare the soy beans for those fermentation urns. They select only high-quality local soy beans, after soaking the dried soy beans for 3-5 hours depending on the weather (humidity and temperature are critical to the process), the soy beans will retain the moisture and become plump again. Then the soaked soy beans will be steamed in the large basket for 12 hours and then rest inside for another 12 hours before they can spread them to cool and coat them with flour.

After the soy beans cool down to a specific temperature, they will mix in the flour and coat the soy beans evenly. This proved not an easy task, which you can experience for yourself if you join us on our Sichuan Fermentation Experience.

To coat the soy beans in flour evenly, a coordinated two-person team is required for maximum efficiency.

After the beans are coated they are spread out on trays and placed into a temperature and humidity-controlled room. Here, they ferment naturally. Within 48 hours, white mold begins to grow and gradually turn green and harden, everything is going smoothly. When the color turns to slightly yellow, it is time to move it in to urns outside.

Each urn is filled with salt water with exact ratios to mix with the fermented soy beans to give it flavor, as well as to preserve it naturally. Both day and night, they open the lid to get sunshine, let it breath and gather natural dew; when it rains, everyone in the factory would come out to close the lids to make sure it is not contaminated.

Under certain temperatures and humidity, the mixture in each urn will be mixed to make sure they are evenly exposed to sunshine and moisture in the air. It would take at least 3 years for the mixture to be mature enough to make soy sauce.

Photo Credit: Xianshi Soy Sauce Factory / A little bamboo sieve is inserted to separate the raw soy sauce from the mixture.

Then the raw soy sauce will be moved to a new urn to be put in direct sunlight in the summer time to get more color as well as a deeper flavor. After more filtration your soy sauce is bottled and ready to be purchased!

When they put the bottled product in front us, I began to truly appreciate the effort that goes into making each bottle of soy sauce. This conviction of generations to preserve the old methods so millions around China and the rest of the world can enjoy pure, high-quality soy sauce - a not so simple sauce - is a truly special gift.

A Tianjin, China native - Chloe has a deep appreciation for all things hotpot. Her appreciation of food and culture runs so deep that after a successful corporate career, she decided to uproot her life in China to attend Le Cordon Bleu Ottawa and Madrid. After working in the culinary industry in Canada, she decided to found Snout & Seek!

No spam, no sharing to third party. Only you and me.

Member discussion